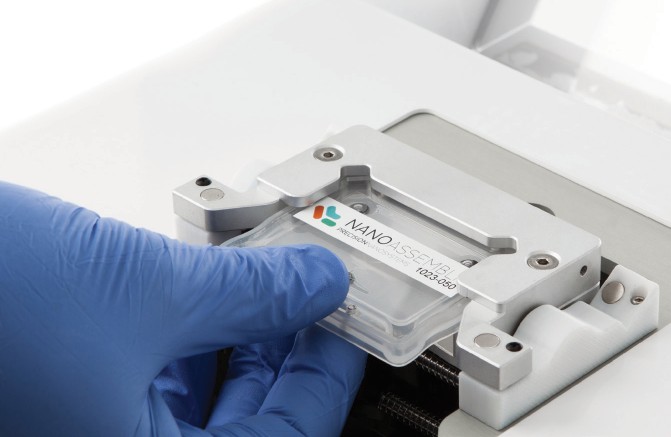

The new Phenom Pharos desktop scanning electron microscope (SEM) is the latest addition to the Phenom Series and is the first desktop SEM solution that includes a field emission gun (FEG). This easy to operate system integrates both advanced hardware design and an intuitive user interface to provide high-resolution images in less than 25 seconds after inserting the sample. Suitable for a wide range of academic and industrial applications, the Phenom Pharos brings the high-resolution capabilities of a field emission source to a desktop model.

Phenom Pharos Specifications:

Source: Field Emissions Gun (FEG)

Maximum magnification = 1,000,000 X

Resolution = < 3nm

Acceleration Voltage range = 2kV – 15kV

Imaging detectors: Backscattered Electron Detector (BSD) + Secondary Electron Detector (SED)

Analysis (optional): Integrated EDS detector

Vacuum observation modes: High, Medium & Low vacuum

The Phenom Pharos SEM will be available for use during two events listed below:

JOIN US AT THE IMC19 MEETING: 9-14 SEPT 2018

The International Microscopy Congress meeting will be held in Sydney at the new International Convention Centre. Visit us at the Thermo Fisher Scientific booth and use the new Phenom Pharos SEM with FEG source.

FREE WORKSHOP AT WESTERN SYDNEY UNI (Parramatta): 19 & 20 SEPT 2018.

Join us and use the Phenom Pharos Desktop SEM. Following each demonstration, the Phenom series of instruments will be available for participants to operate and for sample analysis. Please register by completing the registration form here.

02 9541 3500

02 9541 3500

Quantitative Analysis

Quantitative Analysis Quantitative Analysis

Quantitative Analysis