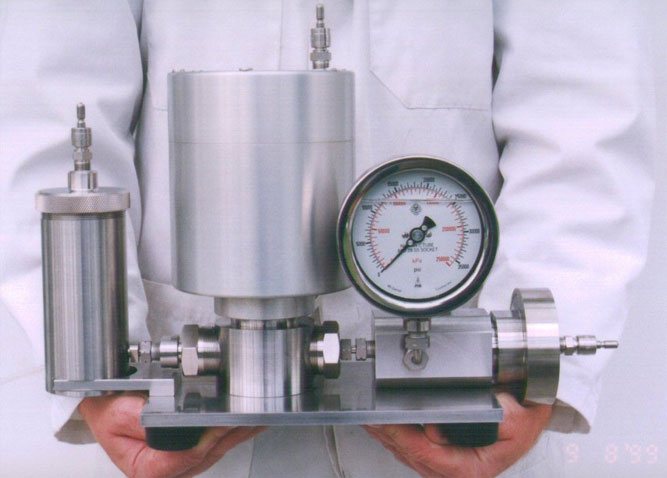

Avestin Emulsiflex C3

The Avestin Emulsiflex C3 is a lab scale, electric motor driven, high pressure homogeniser that rapidly reduces particles and droplets from micron to nanometer sizes.

Avestin Emulsiflex C3

The Avestin Emulsiflex C3 is a lab scale, electric motor driven, high pressure homogeniser that rapidly reduces particles and droplets from micron to nanometer sizes.

| Manufacturer | Avestin |

|---|---|

| Product Series | Emulsiflex |

| Measurement principle | High Pressure Homogenisation |

| Application | Emulsions, Liposome Processing & Mixing |

| Sample type | Dispersion, Emulsions, Liposomes |

| Homogenising pressure | up to 30,000 psi (207 MPa) |

| Throughput | 3 Litres/hr |

| Minimum sample volume | 10ml |

| Valve type | dynamic - pneumatically controlled |

| Temperature control | optional heat exchangers |

| Extruder option | Yes |

Product Overview

High pressure homogenisation is an efficient and easy to use technique for cell disruption and liposome/emulsion processing.

The principle is to pump the sample through a valve with a small aperture. The sample goes from very high pressure on the pump side of the valve to atmospheric pressure on the outlet side of the valve. This extreme change of pressure produces very high shear forces on the sample as it exits the valve. The effect on cells is to disrupt their membranes and the effect on liposomes/emulsions is that they are dramatically reduced in size.

The Emulsiflex C3 uses a dynamic homogenising valve. The benefit of a dynamic valve is that the samples are processed at a constant homogenising pressure. This produces very uniform liposomes and micro emulsions with a narrow particle size distribution.

High pressure homogenisation enables liposomes and emulsions to be processed from microns to nanometer sizes. Cell disruption is also very efficient. Most cells are ruptured in a single pass thereby avoiding over processing and protein damage.

The electric motor driven pump provides homogenising pressures up to 30,000 psi (207 MPa).The processing capacity is up to 3 Litres /hr and the flow rate is independent of pressure. It can process samples as small as 10mL.

The dynamic homogenising valve can be exchanged with a high pressure extruder. This enables the extrusion of liposomes or emulsions through membranes of specific pore sizes.

The EmulsiFlex-C3 requires electric power of 220V at 50Hz and a supply of bottled air.

- Benefits

- Applications

Benefits

Efficient and uniform processing

Most cells are ruptured in a single pass avoiding over processing and protein damage.

Liposome processing

Liposomes and emulsions can be processed from micron to nanometer sizes with narrow

particle size distributions.

Air driven, quiet operation and easy to clean

No “O”rings or gaskets in the product path. Valve parts can readily be removed for inspection.

Temperature control

Heat exchangers can be fitted to the sample inlet and outlet for temperature control.

Applications

- Dispersions: EmulsiFlex homogenisers are involved in the processing of dispersions such as drug dispersions, herb extracts, industrial coatings and pigments

- Liposomes: AVESTIN’s high pressure homogenisers are used all over the world for liposome research and production.

- Emulsions/ Cell rupture: Pharmaceutical emulsions and cells such as yeast can be processed to a reduced size and narrow distribution.

Product Enquiry

SPEAK TO OUR AUSTRALIAN AND NEW ZEALAND TEAM

If you would like to enquire about this product, fill out this form and one of our product specialists will contact you shortly.

If you need help in the operation or repair of an instrument then please contact the Customer Help Centre directly.

Please note, product enquiries are only applicable to Australia, New Zealand, Papua New Guinea and Fiji

Or call us instead at (02) 9541 3500

02 9541 3500

02 9541 3500