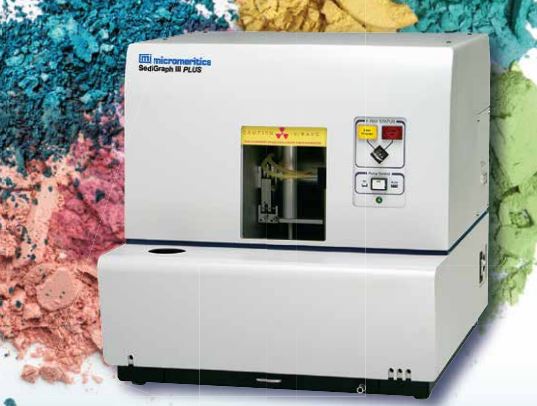

Micromeritics SediGraph III Plus

Micromeritics SediGraph III Plus is a high-resolution particle size analyser that uses the industry standard sedimentation method.

Micromeritics SediGraph III Plus

Micromeritics SediGraph III Plus is a high-resolution particle size analyser that uses the industry standard sedimentation method.

| Manufacturer | Micromeritics |

|---|---|

| Product Series | Micromeritics SediGraph |

| Measurement principle | Sedimentation |

| Application | Density, pore size and volume, Particle Mass and Concentration, Particle Size, Surface Area & Porosity |

| Particle size range | 300 to 0.1 micrometers Equivalent Spherical Diameter |

| Sample Size | 50 mL of dispersed sample - precise concentration is not required |

| Suspending Liquids | Any liquid compatible with sample cell materials and not highly absorptive of Xrays (typical liquids are water, glycols, mineral oils, SediSperse®, and alcohols) |

| Temperature | Ambient +10 to 40 °C |

Product Overview

The Micromeritics SediGraph III Plus is a high-resolution particle size analyser capable of measuring particles from 300 to 0.1 micrometers. For over 50 years, Sedigraph continues to be the worldwide standard in particle size analysis for many industries, including mining, geology, and ceramics.

Sedigraph determines particle size by sedimentation by measuring the gravity-induced settling rates of different size particles in a liquid with known properties as described by Stokes’ Law. Particle mass is measured directly via X-ray absorption. This is a direct measurement; no calibration against reference material or modelling is required. The SediGraph is the only automated particle sizing instrument that directly measures settling velocity. The optional autosampler can run up to 18 samples unattended. It sits securely on top of the SediGraph to conserve bench space and completes most analyses in 15 min or less.

SediGraph uses a modern pumping system that is silent, reliable, and easy to maintain while the temperature-controlled mixing chamber improves repeatability and reproducibility. A highly versatile and interactive reporting system provides a wide range of custom data presentation options.

- Demonstration video

- Benefits

- Applications

- Accessories

Demonstration video

Benefits

- Entire introduced sample is accounted for including any fraction above 300 μm and below 0.1 μm

- Merge data with other particle sizing methods, extending the range of reported data to 125,000 μm (125 mm), excellent for geological applications

- Scans the sedimentation cell from bottom to top to allow accurate inventory of fast-settling particles while minimising the time required to resolve the separation of fine particles

- Fully automatic operation increases sample throughput and reduces operator involvement and the opportunity for human error

- Temperature-controlled analyses ensure liquid properties remain constant throughout the analysis

- Multiple analysis speeds enables choice of the desired combination of speed and resolution that meets your needs

- Real-Time display monitors the cumulative mass plot of the current analysis to allow immediate procedural changes if needed

- Statistical process control (SPC) reports track the performance of processes allowing immediate response to fluctuations

- Plot overlays provide a visual comparison of analysis results from one or more analyses; e.g. a reference or baseline analysis

- Data comparison plots provide graphical displays of the mathematical difference between two data sets (difference from reference plot) or the extent of a data point value above or below a tolerance boundary (out of specification plot)

- Multiple analyser control allows two SediGraphs to be operated simultaneously from a single computer, conserving valuable lab space and optimise data storage.

Applications

Ceramics: The size range of particles and the distribution of mass in each size class strongly affect the ability to sinter a ceramic powder and it’s forming properties as well as the pore size distribution in the finished product. Particle size distribution information helps to determine curing and bonding procedures, control pore structure, ensure adequate green body strength, and produce a final product of desired strength, texture, appearance, and density.

Metal Powders: By controlling particle size, very specific pore characteristics can be designed into a product. Porosity characteristics often are the key to product performance. Similar to ceramics, the particle size distribution is critical to green body and final product strength and density.

Geological/Soil Science: Grain Size affects the moisture-holding capacity of soil, drainage rate, and the soil’s ability to hold nutrients. Grain size is directly related to transport of sediment.

Cosmetics: The appearance, application, and packaging of cosmetics are influenced by the particle size distribution of base powders, such as talc, and the pigments used for coloring.

Pigments: Particle size alone can affect the tinting strength of a color. As tinting strength goes up, the quantity of pigment needed to produce required color intensity goes down. The particle size affects the hiding power of the paints. Also the particle size distribution influences gloss, texture, color saturation and brightness.

Catalysts: Particle size affects the catalytic activity of a metal for structure-sensitive catalytic reactions.

Construction Materials: Particle size of cement affects setting time and strength characteristics of finished concrete and cement.

Minerals and Inorganic Chemicals: Reactivity of materials is dependent upon exposed surface area and thus particle size distribution.

Abrasives: A properly balanced size distribution of abrasive grains and powders is a fundamental consideration whether the material is to be used in slurries, dry blasting, or bonded abrasive tools. Uniform particle size assures precise flow rates through blast machines and is a critical determination in media management when recycling the abrasive material.

Accessories

High throughput with optional MasterTech autosampler

For automatic sample preparation. Redisperses samples and transfers them to the SediGraph for analysis. Includes built-in mechanical stirrer and ultrasonic probe.

Product Enquiry

SPEAK TO OUR AUSTRALIAN AND NEW ZEALAND TEAM

If you would like to enquire about this product, fill out this form and one of our product specialists will contact you shortly.

If you need help in the operation or repair of an instrument then please contact the Customer Help Centre directly.

Please note, product enquiries are only applicable to Australia, New Zealand, Papua New Guinea and Fiji

Or call us instead at (02) 9541 3500

02 9541 3500

02 9541 3500